Hydraulic Ball Valves: A Comprehensive Guide for Businesses

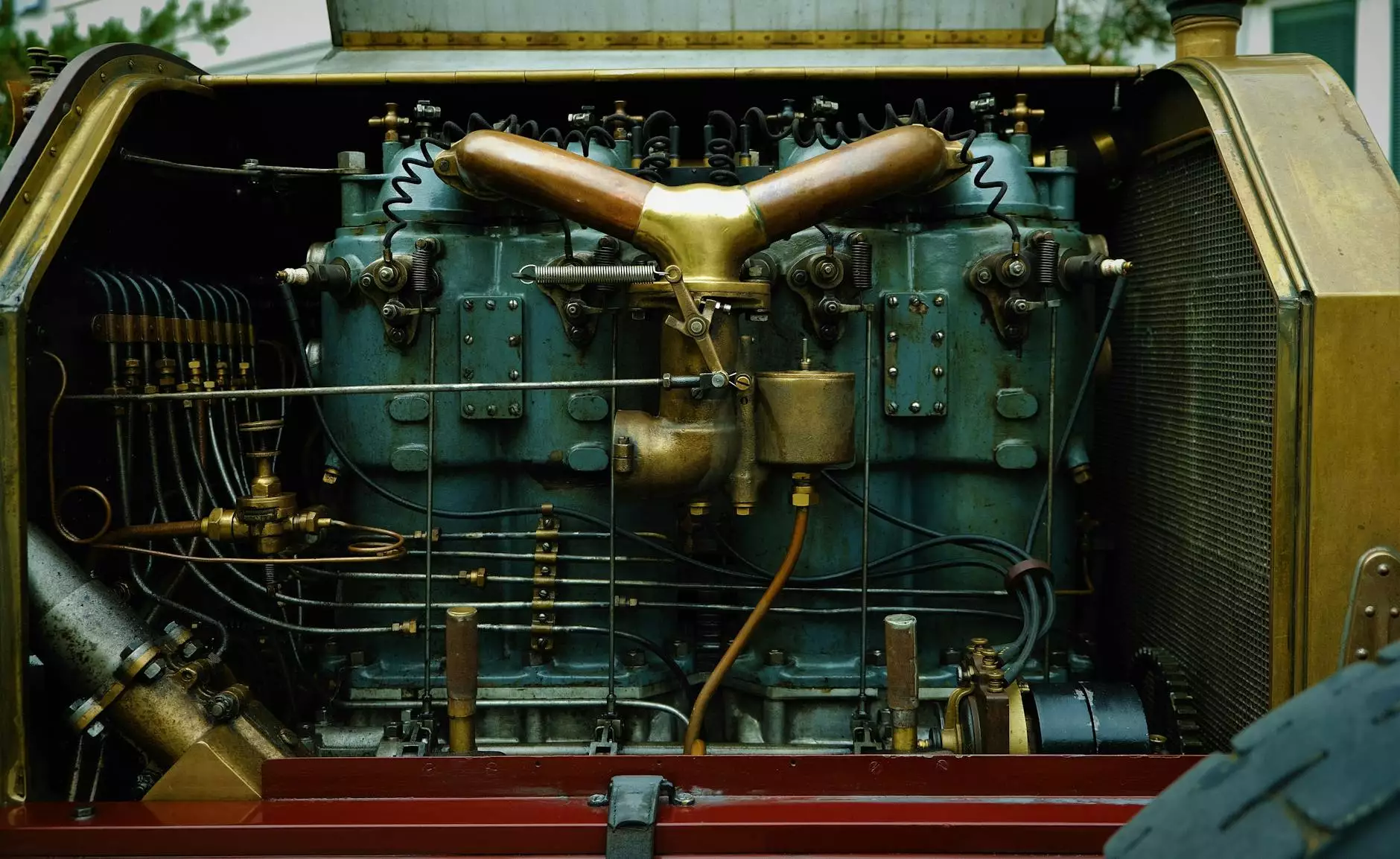

When it comes to industrial applications, the choice of fittings plays a crucial role in the performance and reliability of the systems in which they are used. One of the most essential components in hydraulic systems is the hydraulic ball valve. This article delves into the intricacies of hydraulic ball valves, their advantages, applications, and the impact they have on business operations.

What is a Hydraulic Ball Valve?

A hydraulic ball valve is a type of stop valve that uses a spherical disc, known as a ball, to control the flow of fluid through it. The ball has a hole, or port, through its center that allows flow when aligned with the pipeline. When the valve is turned 90 degrees, the ball’s port is perpendicular to the flow, effectively stopping it. This design makes hydraulic ball valves particularly advantageous for applications requiring a reliable seal.

Key Features of Hydraulic Ball Valves

Understanding the key features of hydraulic ball valves can help businesses make informed purchasing decisions. Here are some of the critical characteristics:

- Durability: Hydraulic ball valves are constructed from robust materials like stainless steel, bronze, or PVC, ensuring a long lifespan even in demanding environments.

- Efficiency: The spherical shape of the ball allows for minimal resistance to flow, meaning less energy is required to pump fluids through the valve.

- Leakage Prevention: The design minimizes the risk of leaks, providing peace of mind for businesses focused on safety and efficiency.

- Versatility: Hydraulic ball valves can be used in various applications, including water treatment, oil and gas, chemical processing, and more.

The Working Mechanism of Hydraulic Ball Valves

To appreciate the role of hydraulic ball valves, it is essential to understand how they work. The operational mechanism involves:

- Opening: Turning the valve handle rotates the ball within the valve body, aligning the hole in the ball with the flow path, thus allowing fluid to pass through.

- Closing: As the handle is turned back, the ball rotates, blocking the flow of fluid.

- Sealing: The seats on either side of the ball help create a tight seal, preventing leaks when the valve is closed.

Advantages of Using Hydraulic Ball Valves

There are several advantages to utilizing hydraulic ball valves in business operations:

1. Quick Operation

The design of hydraulic ball valves enables quick operation, allowing for rapid opening or closing, which is crucial in many industrial applications.

2. Low Operating Torque

Hydraulic ball valves require minimal effort to operate compared to other valve types, making them user-friendly and reducing the risk of operator fatigue.

3. Full Flow Capability

The straight-through design of the valve provides full flow capability, reducing pressure drops and improving overall system efficiency.

4. Minimal Maintenance Needs

Due to their simple design, hydraulic ball valves require minimal maintenance, saving time and reducing costs for businesses.

5. High Reliability

These valves are known for their reliability, and with proper handling, they can function effectively even under high pressure and fluctuating temperatures.

Applications of Hydraulic Ball Valves

Hydraulic ball valves find applications across various industries, making them versatile fittings for sale. Here are some primary applications:

- Oil and Gas: Used in upstream, midstream, and downstream processes for flow control and isolation.

- Chemical Processing: Essential for controlling the flow of corrosive and hazardous fluids.

- Water Treatment: Commonly used to manage the flow of water in purification processes.

- HVAC Systems: Utilized in heating, ventilation, and air conditioning applications for regulating fluid dynamics.

- Power Generation: Used in steam and water systems to manage flow effectively.

Choosing the Right Hydraulic Ball Valve

When selecting the best hydraulic ball valve for your business needs, consider the following factors:

1. Material

The valve material should match the fluid being handled to prevent corrosion and ensure longevity. Common materials include stainless steel for corrosive applications and brass for general-purpose use.

2. Size and Connection Type

Choose a valve size that fits the pipe diameter and ensure that the connection type, whether threaded, flanged, or welded, matches your application requirements.

3. Pressure and Temperature Ratings

Ensure that the valve can handle the operational pressure and temperature of your system to prevent failures and leaks.

4. Certification Standards

Check for industry standards and certifications such as ISO, API, and ASME that ensure reliability and safety in your operational environment.

Maintenance Tips for Hydraulic Ball Valves

To maintain the reliability and longevity of hydraulic ball valves, follow these maintenance tips:

- Regular Inspection: Periodically inspect valves for wear, corrosion, or damage to maintain performance.

- Lubrication: Use appropriate lubricants to reduce wear and tear on moving parts.

- Sealing Check: Ensure seals are intact, as worn seals can lead to leaks and system failures.

- System Testing: Conduct routine testing of the hydraulic system to check for pressures and flow rates.

The Impact on Business Operations

Using high-quality hydraulic ball valves significantly impacts business operations in numerous ways:

1. Enhanced Safety

Reliable valve systems contribute to safer working environments by minimizing the risk of leaks and system failures.

2. Cost Efficiency

Reduced maintenance and operational costs through reliable valve performance can improve the bottom line for businesses.

3. Improved Efficiency

Efficient flow control leads to optimized processes, minimizing energy consumption and maximizing productivity.

4. Compliance

Meeting industry standards and regulations through proper valve selection and maintenance ensures compliance, reducing the risk of penalties for businesses.

Conclusion

In conclusion, hydraulic ball valves are essential for businesses that require reliable and efficient fluid control systems. With their numerous advantages, applications, and minimal maintenance needs, they are a worthwhile investment for any operation. By understanding the key characteristics and choosing the right fittings, businesses can optimize their operations, ensuring safety and productivity in their processes.

Explore Quality Hydraulic Ball Valves

If you are interested in sourcing high-quality hydraulic ball valves, visit fitsch.cn for a wide range of fittings for sale tailored to your business needs. Ensure you harness the benefits of reliable fittings that can make a significant difference in your operations.